Baffled by all the choices and technical terms when you need your business cards, flyers, brochures, posters and more professionally printed? Solopress’ printing guru Tim Hann is here with expert advice on how to get your commercial print work done right every time…

In this easy-to-understand Buyers Guide to Printing, Solopress will highlight and explain the main considerations to take into account when purchasing any printed items from a commercial printer. They are presented in no particular order, as each will carry a varying degree of importance to the individual. However, the most common questions asked by our customers are “How Soon?“ (Turnaround) and “How Much?” (Cost).

Printing Turnaround Times – How Soon?

The golden rule here is to be realistic, don’t expect the impossible and you won’t be disappointed. In all cases, Solopress will meet our commitment. However, there may be times when we will be unable to meet your deadlines.

Common factors that can affect turnaround times:

- If a bespoke paper/board is required it may take time for the delivery to arrive as this will have to ordered in especially and we are governed by the product’s availability.

- The quantity required. We are sometimes asked for extremely large quantities and time will be required to fulfil the complete order.

- The finishing and any special, extra requirements for the order. The more complex these are, the longer the process takes to complete the order.

- Delivery. This can sometimes be an issue when sending an order overnight on a national carrier. In this event, we will endeavour to chase the delivery and rectify any issues. When using overnight national couriers we are unable to confirm a delivery time until the day of delivery. If you would like further information, please call Solopress on 01702 460047 and we will help you in any way we can.

All this said we are pleased to confirm that 99.99% of all orders placed with Solopress are delivered to our customers on time.

Printing Costs – How Much?

The simple rule of thumb here is: the more you have, the more you pay. Similarly complexity = cost. Keep it simple and it keeps the cost down!

Print costs can be broken down into these three main areas for both the litho (lithographic) and digital methods of printing:

- Design

- Finishing (see below for more details)

Design

On our website you will find a list of design charges for the production of artwork. If you choose to opt for this quick and hassle-free route, we have a very talented design team ready to discuss your needs. All artwork produced will be proofed. Proofs are available in various formats to suit your needs. No design will go to press until a sign off has been received to say that it is approved and ready for print.

Alternatively, you may wish to design and supply your own artwork. Templates are readily available and guidelines outlining how best to supply the final file. These include acceptable file formats and layouts including bleed trims and resolution size. Our guidelines are for both digital and litho output. Please remember to provide crop marks around all your supplied artwork. Failing to add these in your artwork may result in you not receiving the print job to your specification.

Litho

This process includes the cost of the material required – the paper/board, plates, ink and make-ready charges. It also includes price per 1,000 sheets on the press. With a greater quantity, the unit cost per item drops.

Digital

This is similar. However, the cost of the machine is denoted by the number of individual items. You pay the same price for one item as you would for 500 items. This produces a cut-off point at around 1,000 items where litho becomes a more viable and economical solution.

One-off banners and posters etc. may be charged by the metre.

If you have any queries you can speak to our friendly and knowledgeable sales consultants on 01702 460047.

Materials and Substrates used in Printing

Solopress cater for all ranges of stocks, ranging from papers to boards.

Litho stocks and substrates:

Boards and papers are can be broken down into uncoated and coated materials. Uncoated paper is often referred to as bond, cartridge or offset. An uncoated board is referred to as pulp. Coated papers can be subdivided in basically three categories or finishes: Matt, Silk and Gloss. The finish is commonly achieved by a coating of chalk and then either a blade is drawn over the stock crushing the chalk into the fibres or the paper being passed through a series of rollers at extremely high speed (this process is often referred to as calendared).

Bespoke materials:

Bespoke materials are available upon request by our customers. These can range from self-adhesive labels, NCR (no carbon required), watermarked papers or finished papers or boards (such as laid or hammer finish).

Digital stocks and substrates:

A wide range of digital compatible stocks is available, from coated/uncoated boards and papers to vinyl and satin stocks used for display purposes.

Paper sizes

Paper sizes are measured using the European metric system (mm) and the industry standard SRA system of measurement. The sheet size should not be confused with the trim/finished size. Some paper sizes still refer to the imperial sizes, these are few and far between and only affect the bespoke papers.

Print size:

- SRA8 = 80mm x 56mm

- SRA7 = 113mm x 80mm

- SRA6 = 160mm x 113mm

- SRA5 = 225mm x 160mm

- SRA4 = 320mm x 225mm

- SRA3 = 450mm x 320mm

- SRA2 = 640mm x 450mm

- SRA1 = 900mm x 640mm

- SRA0 = 1280mm x900mm (not available as a sheetsize)

Trim/Finished size:

- A8 = 52.5mm x 74.25mm

- A7 = 74.25 mm x 105mm

- A6 = 105mm x 148.5mm

- A5 = 148.5mm x 210mm

- A4 = 210mm x 297mm

- A3 = 297mm x 420mm

- A2 = 420mm x 594mm

- A1 = 594mm x 840mm

- A0 = 841mm x 1189mm

Why do we print on larger paper? All printing presses need to hold/grip the stock to prevent movement of the individual sheet as it passes through the press. This area is known as the grip and is a non-printable area. On litho presses this area is approximately 12mm from the edge of paper. On digital machines this can be considerably less, but still needs to taken into account when designing your artwork for print.

Paper weights

Papers and boards also use the European metric system, grams per square metre (gsm). The weight is calculated based on the total weight of a single sheet of paper or board 1-metre x 1 metre. The oddment to this rule is uncoated boards as this can be referred to by microns (mic) that denote their thickness.

Standard paper weights:

- Uncoated – 80gsm, 100gsm, 120gsm and 160gsm

- Coated – 100gsm, 130gsm, 150gsm and 170gsm

- Standard board weights/microns

- Uncoated – 280mic and 380mic

- Coated – 200gsm, 230gsm, 250gsm, 280gsm, 300gsm, 350gsm and 400gsm

Digital weights:

As above but also 190gsm satin Epson papers and pieces of vinyl up to 500gsm

Printing Quality

Solopress.com holds ISO 9001 accreditation an industry standard for assured quality. We are continually assessed to ensure that high standards are maintained throughout all working practices within the working environment.

Litho

All litho plates are run with a 175 screen dpi (dots per inch) and at 2,400 dpi (lines per inch) producing a high-resolution output. The rule here is input resolution twice the output resolution. This is why we request supplied files at least 300dpi.

Digital

Produces a continuous / conti-tone image with no visible dot.

Both these different methods of printing produce images of the highest quality. There is debate as to which is better, and to some degree, it is a personal choice. What you need to remember here is we can only produce what we are supplied. If poor low-resolution images are supplied then this will produce a poor low-resolution print.

Environmental Issues

This can feature quite highly on the wish list of print requirements for our customers. That’s why we take our responsibilities to preserve the planet very seriously, as well as offering the widest choices and best prices available for eco-friendly printing. As this is such a fundamental part of our business, Solopress holds ISO 14001 accreditation, the industry standard for Environmental Management and practices.

Inks

Solopress uses eco inks derived from vegetable oil rather than a mineral oil base for everything we print.

Papers

The majority of papers that are used are responsibly sourced.

This is an internationally recognized organization that promotes responsible forest management and conservation globally. Papers are labelled according to their environmental status, i.e. what constitutes the make up of the paper used.

There are very few 100% recycled papers on the market that are economically viable to use. However, the majority of papers available are environmentally friendly. The whiteness of this paper is achieved through oxidization rather than through bleaching with chlorine. Also, a large portion of the paper is reconstituted pulp cores. The core of the paper is too curly to use, so it is repulped during the manufacturing stage.

Print Colour

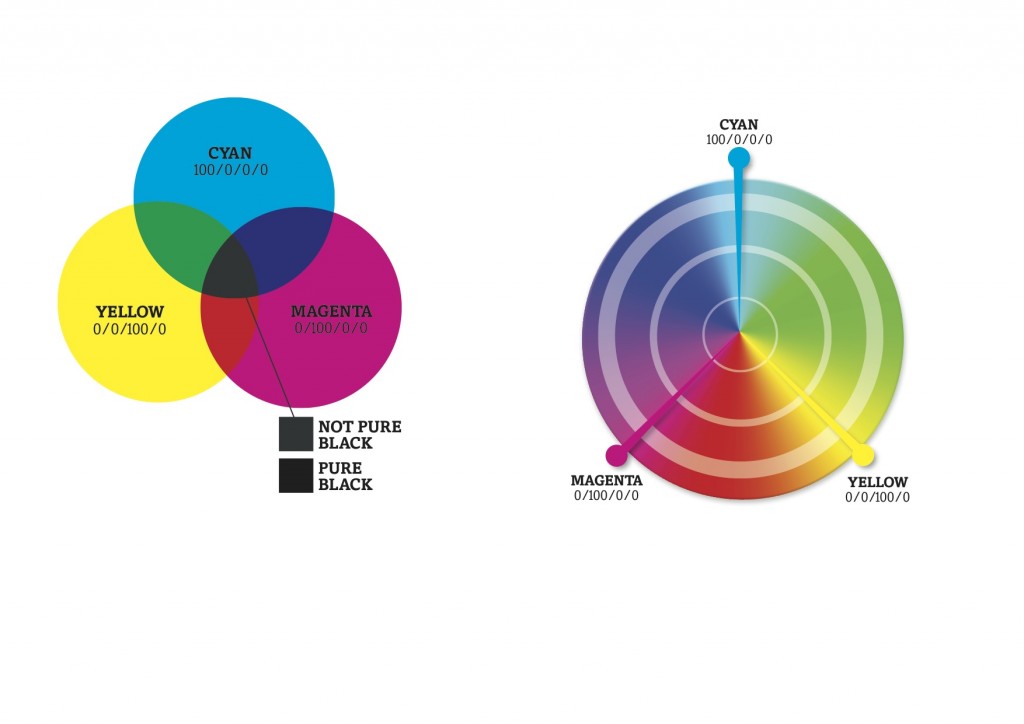

Four colour process or spot colours?

How colour can be affected using different materials:

Firstly, all general inks will dry by one of two methods depending on the material they are printed. With all uncoated materials, the ink dries by penetration. Here the ink soaks into the fibres and dries over a longer period of time. This needs to be taken into account when ordering pulp or uncoated materials. It is slow drying. With coated materials, the ink sits on the surface and dries by oxidization. Matt coated stocks are slower driers than silk which is slower than gloss coated materials. Again, this should be considered when placing your order. The two main criteria for the appearance of colour is the stock and whether the image is printed CMYK or in spots. The choice of method used is often denoted by cost rather than the finished result. Blocks/areas of colour produced out of CMYK can lose their vibrancy simply because the individual colour may be made up with a percentage of black or blue. The same result can happen when printing onto uncoated stocks as the ink soaks into the fibres. This is less likely to happen on coated materials due to the different drying process.

Don’t RGB It!

The CMYK process is not to be confused with Red (R) Green (G) Blue (B). This RBG colour breakdown is specifically designed for electronic screens such as monitors, televisions and digital cameras. This format has a wider spectrum of colour and is favoured by photographers. However, for the litho printing process, all RGB images have to be converted to CMYK.

Print Finishing

Finishing is an additional procedure post printing other than trimming and packing. The easy rule to follow is: the more finishing procedures involved, the greater the cost.

Lamination

There are matt and gloss lamination finishes. When printing in spot colours, lamination can affect the colour – especially those with either reflex blue or rubine red in their make up. Due to the ammonia in glue bleaching can occur.

Foiling

Often used as a security feature and on high-end products. Samples are available upon request.

UV

This is available as an all-over effect, or as a spot finish. This is a high gloss cured by intense ultraviolet light.

Folding

Standard folds include:

- Gatefold/bifold – in half

- Roll/trifold – in three

- Z/concertina fold

- Double gatefold

- Closed gatefold

- Parallel fold

Stapling/Stitching

Referred to as stitching there are three standard types of stitching:

- One stitch top left or right – this is for loose leaf binding

- Stab stitch – usually with two wires for loose leaf and to strengthen pads

- Centre/saddle stitch with two wires

Drilling

The automated process of applying holes from 2mm – 6mm as standard when producing documentation for folders or swing tags and lanyards.

PUR/Perfect binding

A process of binding books/brochures with large amounts of pages, usually greater than 48 printed pages.

Please remember to incorporate a margin of minimum 10mm at the binding edge to allow for the hinge score.

Die-cutting/Creasing

This will require a one-off cost for producing the die. Prices vary as to the complexity of the die.

Bench work/other bespoke finishing procedures

This includes the making up of folders, collating, padding, numbering and any other bespoke requirement to fulfil your order.

Printing Buyers Guide In Brief:

- Know what you want – including the quantity, materials, finishing, etc.

- Supply your own artwork following the guidelines on our website – or use the services of our in-house design studio.

- Keep it simple.

- Be realistic in turnaround times.

Finally, if you are in any doubt please contact Solopress on 01702 460047 to discuss your printing queries.